| |

|

1.0 UN Packing Groups

1.1 Substances of all classes, other than class 1, 2, 5.2, 6.2 and 7 and the self-reactive substances of class 4.1, are assigned to three Packing Groups in accordance with the degree of danger presented by the substance in transport. The Packing Groups have the following means:

? |

| ?Packing group I |

'Substances presenting high danger |

| ?Packing group II |

'Substances presenting medium danger |

| ?Packing group III |

'Substances presenting low danger |

|

?

1.2 Grouping Criteria for:

?

1.2.1 Packing Group Assignment for Flammable Liquids (Class 3)

? |

PG |

Flashpoint in ¢XC Closed-cup (c.c.) |

Initial boiling point in ¢XC |

I

II

III |

¡V

> 23

>= 23 to <= 61 |

<= 35

> 35

> 35 |

|

?

1.2.2 Packing Group Assignment for Substances of Class 4.2

?

|

PG |

Substances liable to spontaneous combustion |

I |

'All pyrophoric solids & liquids

|

II |

'Self-heating substances which give a positive result in a test using 25 sample cube at 140¢XC

|

III |

'Other self-heating substances which do not meet the criteria for PG II

|

|

?

1.2.3 Packing Group Assignment for Substances of Class 4.3

?

|

PG |

Substances which, in contact with water, emit flammable gases

|

I |

'Any substance which reacts vigorously with water at ambient temperatures & demonstrates generally a tendency

'for the gas produced to ignite spontaneously, or which reacts readily with water at ambient temperatures such that

'the rate of evolution of flammable gas is equal to or greater than 10l per kilogram of substance over any one

'minute

|

II |

'Any substance which reacts readily with water at ambient temperatures such that the maximum rate of evolution of

'flammable gas is equal to or greater than 20l per kilogram of substance per hour, & which does not meet the

'criteria for PG I

|

III |

'Any substance which reacts slowly with water at ambient temperatures such that the maximum rate of evolution of

'flammable gas is equal to or greater than 1 litre per kilogram of substance per hour, & which does not meet the

'criteria for PGs I or II

|

|

?

1.2.4 Packing Group Assignment for Substances of Class 5.1

?

|

PG |

Solid Oxidizing Substances

|

Liquid Oxidizing Substances |

I |

'Any substance which, in the 4:1 or 1:1 sample-to-

'cellulose ratio (by mass) tested, exhibits a mean'

'burning time less than the mean burning time of a

'3:2'mixture'(by mass) of potassium bromate & cellulose

|

'Any substance which, in the 1:1 mixture (by mass)

'of'substance & cellulose tested, spontaneously ignites;

'or'the mean pressure rise time of a 1:1 mixture (by

'mass) of'substance & cellulose is less than that of a 1:1

'mixture'(by mass) of 50% perchloric acid & cellulose

|

II |

'Any substance which, in the 4:1 or 1:1 sample-to-

'cellulose ratio (by mass) tested, exhibits a mean'

'burning

'time equal to or less than the mean burning

'

'time of a'2:3 mixture (by mass) of potassium bromate & '

'cellulose & the criteria for PG I are not met

|

'Any substance which, in the 1:1 mixture (by mass)

'of'substance & cellulose tested, exhibits a mean

'pressure rise time less than or equal to the mean

'pressure rise 'time of a 1:1 mixture (by mass) of 40%

'aqueous sodium'chlorate solution& cellulose; & the

'criteria for PG I are not met

|

III |

'Any substance which, in the 4:1 or 1:1 sample-to-

'cellulose ratio (by mass) tested, exhibits a mean

'burning time equal to or less than the mean burning '

'time 'of a 3:7 mixture (by mass) of potassium bromate & '

'cellulose'& the criteria for packing groups I & II are not 'met

|

'Any substance which, in the 1:1 mixture (by mass)

'of'substance & cellulose tested, exhibits a mean

'pressure'rise time less than or equal to the mean

'pressure rise'time of a 1:1 mixture (by mass) of 65%

'aqueous nitric 'acid & cellulose; & the criteria for

'PGs I & II are not met

|

|

?

1.2.5 Packing Group Assignment for Toxic Substances of Class 6.1

? |

Administration through Oral Ingestion, Dermal Contact & Inhalation of Dusts & Mists |

PG |

Oral Toxicity

LD50

(mg/kg) |

Dermal Toxicity

LD50

(mg/kg) |

Inhalation Toxicity by Dusts & Mists

LC50 (One Hour)

(mg/l) |

I |

<= 5 |

<= 40 |

<= 0.5 |

II |

> 5 ¡V 50 |

> 40 ¡V 200 |

> 0.5 ¡V 2 |

III |

Solids> 50 ¡V 200

Liquids> 50 ¡V 500 |

> 200 ¡V 1000

> 200 ¡V 1000 |

> 2 ¡V 10

> 2 ¡V 10 |

|

?

1.2.6 Packing Group Assignment for Corrosive Substances of Class 8

?

|

PG |

Corrosive Substances

|

I |

'Substances that cause full thickness destruction of intact skin tissue within an observation period of up to 60

'minutes starting after an exposure time of 3 minutes or less

|

II |

'Substances that cause full thickness destruction of intact skin tissue within an observation period of up to 14 days

'starting after an exposure time of more than 3 but not more than 60 minutes

|

III |

'Substances that cause full thickness destruction of intact skin tissue within an observation period of up to 14 days

'starting after an exposure time of more than 60 minutes but not more than 4 hours; or are judged not to cause full

'thickness destruction of intact skin tissues but which exhibit a corrosion rate on steel or aluminium surfaces

'exceeding 6.25 mm a year at a test temperature of 55¢XC

|

|

| |

?

?

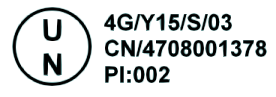

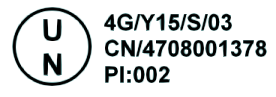

2.0 UN Packaging Symbol & Code

?

|

| |

Sample UN Marking |

|

|

UN |

?The United Nations packaging symbol. |

4 |

?Packaging Used

?

???1. Drum/Pail

???2. Wooden Barrel

???3. Jerrican

???4. Box

???5. Bag

???6. Composite Packaging

|

G |

?Material used for Construction

?

???A. Steel (All Types & Surface Treatments)

???B. Aluminum

???C. Natural Wood

???D. Plywood

???F. Reconstituted Wood

???G. Fiberboard

???H. Plastics Material

???L. Textile

???M. Paper, Multiwall

???N. Metal (often than Steel & Aluminum)

???P. Glass, Porcelain or Stoneware |

Y |

?Packing group or groups for which the design type has been successfully tested

?

???X?for Packaging groups I, II, III

???Y?for Packaging groups II and III

???Z?for Packaging group III only |

15 |

?The maximum gross mass in Kilograms; or for packaging intended for Liquids, this marking

?will indicate the density or specific gravity of material packed |

S |

?Packaging used for containing solids or inner packagings |

03 |

?The year during which the packaging was manufactured

|

CN |

?The State authorizing the allocation of the mark

|

4708 |

?The name of the inspection body specified by China competent authority

|

1378 |

?The name of the manufacture specified by China competent authority

|

PI:002 |

?The batch number of production |

|

?

How to Read the Names of the Inspection Bodies Specified by China Competent Authority?

?

|

Province/City |

Code |

Province/City |

Code |

Province/City |

Code |

Beijing |

1100 |

Fujian |

3500 |

Zhuhai |

4800 |

Tianjin |

1200 |

Jiangxi |

3600 |

Sichuan |

5100 |

Heibei |

1300 |

Shandong |

3700 |

Guizhou |

5200 |

Shanxi |

1400 |

Xiamen |

3800 |

Yunnan |

5300 |

Inner Mongolia |

1500 |

Ningbo |

3900 |

Tibet |

5400 |

Liaoning |

2100 |

Henan |

4100 |

Chongqing |

5500 |

Jilin |

2200 |

Hubei |

4200 |

Shanxi |

6100 |

Heilongjiang |

2300 |

Hunan |

4300 |

Gansu |

6200 |

Shanghai |

3100 |

Guangdong |

4400 |

Qinghai |

6300 |

Jiangsu |

3200 |

Guangxi |

4500 |

Ningxia |

6400 |

Zhejiang |

3300 |

Hainan |

4600 |

Xinjiang |

6500 |

Anhui |

3400 |

Shenzhen |

4700 |

|

|

|

| |

?

?

3.0 Types of Packagings

?

? ¡@

3.1 Controlling Packagings

?

Any packaging, such as a receptacle, cartridge or case of an article or device, is designed to retain and be directly in contact with a substance or mixture of substances therein and form an integral part of the article or device and is required in order that the device or article may function correctly when used.

? |

Disposable LPG Cylinders |

|

Refillable LPG Cylinders |

|

Aerosol Products |

|

Tear Gases |

|

Pepper Spray |

|

Fireworks |

|

Batteries |

|

|

?

?

3.2 Protective Packagings

?

Any packaging is prepared to perform both protection and containment functions together with any other necessary components and manners for safe and convenient movement of substances, materials and articles. Taking into account the functions in transport, It should be considered extending the concept to include any transport unit that is really the most protective.

?

|

Inner Packagings |

|

Outer Packaging |

|

Composite Packagings |

|

Intermediate Packagings |

|

Intermediate Bulk Containers |

|

Large Packaging |

|

Salvage Packagings |

|

Reconditioned Packagings |

'Includes metal drums, plastic drums and jerricans that are reconditioned. |

Remanufactured Packagings |

'Includes: 1) metal drums that are produced as a UN type from a non-UN type

'or converted from one UN type to another UN type or undergo the replacement

'of integral structural components; 2) plastics drums that are converted from

'one UN type to another UN type or undergo the replacement of integral

'structural components.

|

Re-used Packagings |

|

Special Packagings |

|

|

?

?

BACK TO TOP

?

|